F1 2026 – Will the 2026 Ferrari F1 engine really feature a steel cylinder head? While technically possible, the rumor of it being produced via Additive Manufacturing (3D Printing) is inaccurate. Here is a technical analysis of why current technology cannot yet meet F1 tolerances for such a critical component.

- How Additive Manufacturing Works in Formula 1

- Laser Powder Bed Fusion: The Ferrari-Renishaw Partnership

- Is a Fully 3D-Printed Cylinder Head Realistic?

- Why a Steel Cylinder Head Cannot Be 3D Printed (Yet)

- Truly “AM-Friendly” Components

- Material Science: Steel vs. Aluminum

- Beyond the “Innovation” Myth

- Final Analysis

Recently, reports (originally sourced from Motorsport.com) suggested that Ferrari has developed a steel cylinder head for its 2026 Power Unit using 3D printing technology. However, the technical reality is quite different: it is currently impossible to produce a full cylinder head with the required tolerances using Additive Manufacturing (AM). While Ferrari is a pioneer in AM, the technology is reserved for selective parts, not components as massive and critical as the cylinder head.

How Additive Manufacturing Works in Formula 1

Additive Manufacturing builds components layer by layer from a digital model, eliminating the need for complex molds and tooling. This drastically reduces the lead time between design and the finished part. In the high-pressure world of Formula 1, this allows for rapid iterations on geometries and performance—a vital competitive advantage.

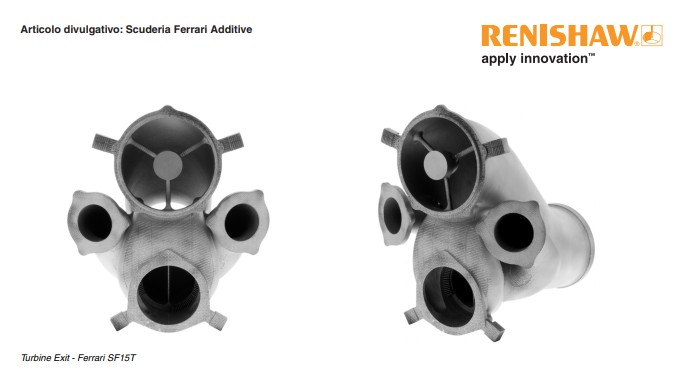

Laser Powder Bed Fusion: The Ferrari-Renishaw Partnership

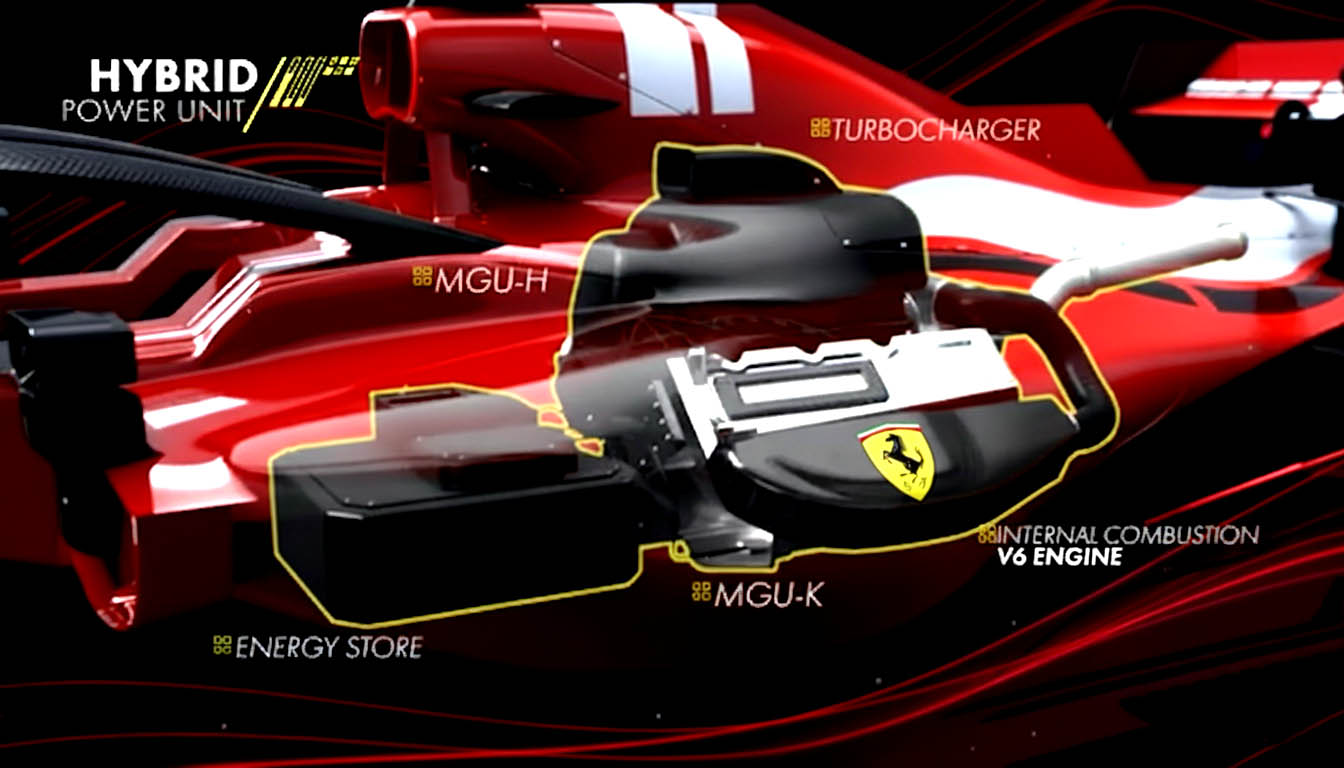

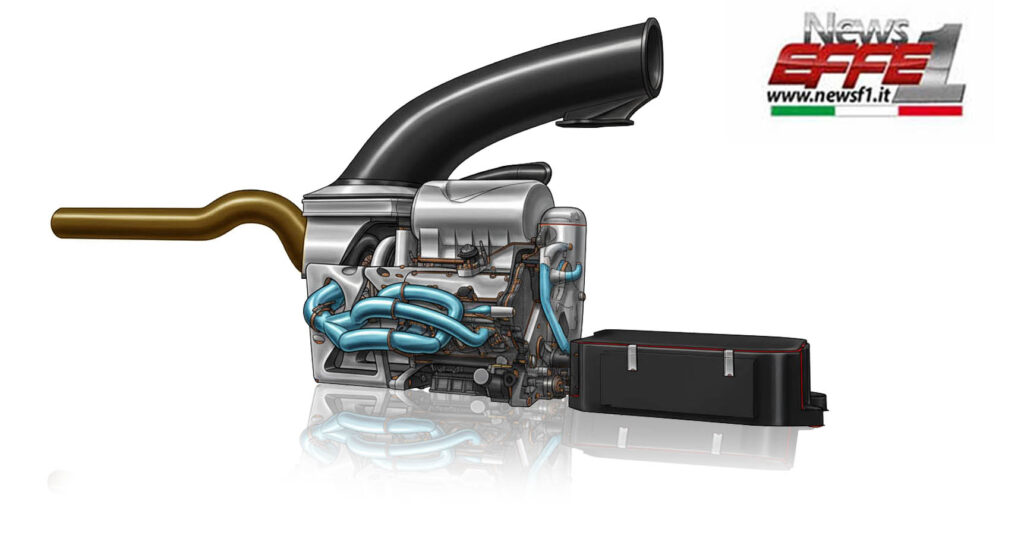

Ferrari collaborates with Renishaw, utilizing Laser Powder Bed Fusion (LPBF). In this process, metallic powder is fused layer by layer by a high-precision laser in a chamber filled with inert gas (usually Argon) to ensure optimal metallurgical quality. These machines operate continuously, recovering over 95% of the unused powder, allowing for the uninterrupted production of highly complex components.

Is a Fully 3D-Printed Cylinder Head Realistic?

Theoretically, a cylinder head could be printed. Modern LPBF machines can handle significant volumes and process metal alloys with excellent mechanical properties. However, the real question isn’t whether it’s possible, but whether it is rational.

A cylinder head is a massive structural component subject to:

- Extreme mechanical loads.

- High thermal gradients.

- Rapid heating and cooling cycles.

Printing such a part would result in extremely long production times, significant residual stress accumulation, and the need for exhaustive post-processing, such as thermal stress relief, HIP (Hot Isostatic Pressing), and extensive precision machining. In the cost-cap era of F1, such a solution is currently unjustifiable from an industrial standpoint.

Why a Steel Cylinder Head Cannot Be 3D Printed (Yet)

According to an F1 engine engineer, printing a cylinder head to the microscopic tolerances required by modern Power Units is not feasible with any current machinery.

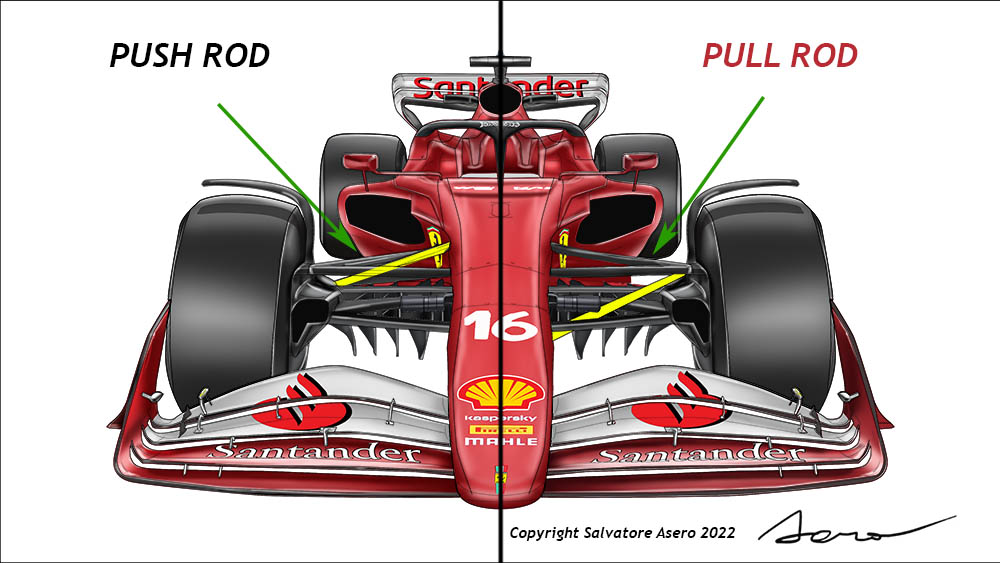

Currently, Additive Manufacturing is used for selective components, such as structural suspension elements, with future developments focused on uprights. A cylinder head remains too critical and complex for the current limitations of metal 3D printing.

Truly “AM-Friendly” Components

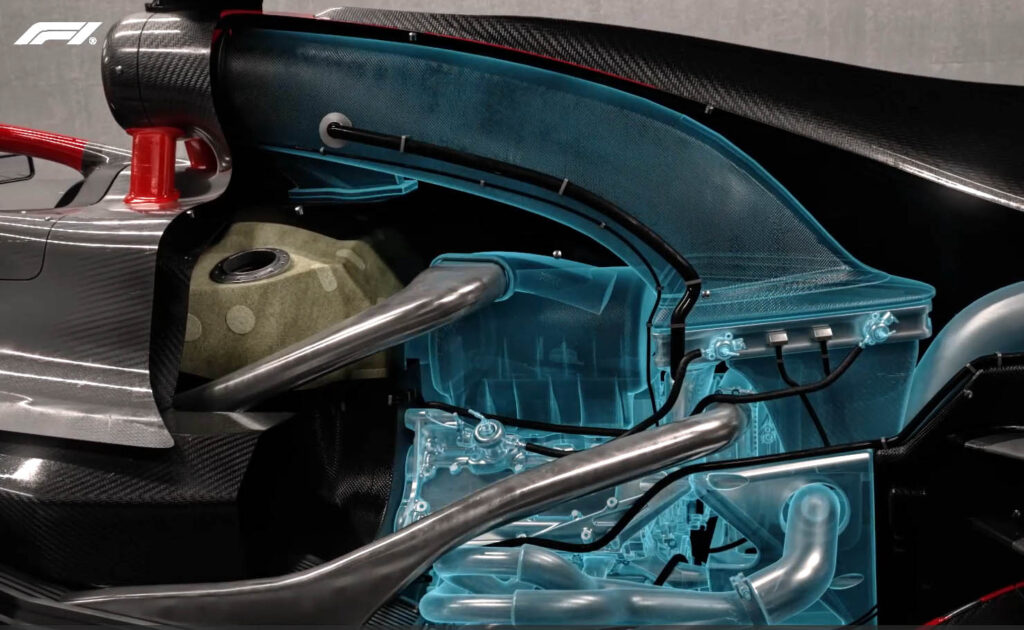

Additive Manufacturing excels where fluid dynamics and thermal control are paramount. This includes:

- Internal cooling ducts with conformal circuits.

- Integrated manifolds.

- Complex heat exchangers.

In these areas, geometric freedom improves efficiency without attempting to replace traditional high-precision casting or machining for the main engine block structures.

Material Science: Steel vs. Aluminum

Traditional F1 cylinder heads are made of Aluminum—lightweight and thermally conductive, but limited under extreme pressure. Steel offers superior mechanical and thermal resistance but adds significant weight. While AM allows for thinner walls and optimized geometries, making the selective use of steel viable, it is not yet applicable to a full-scale, critical component like the cylinder head.

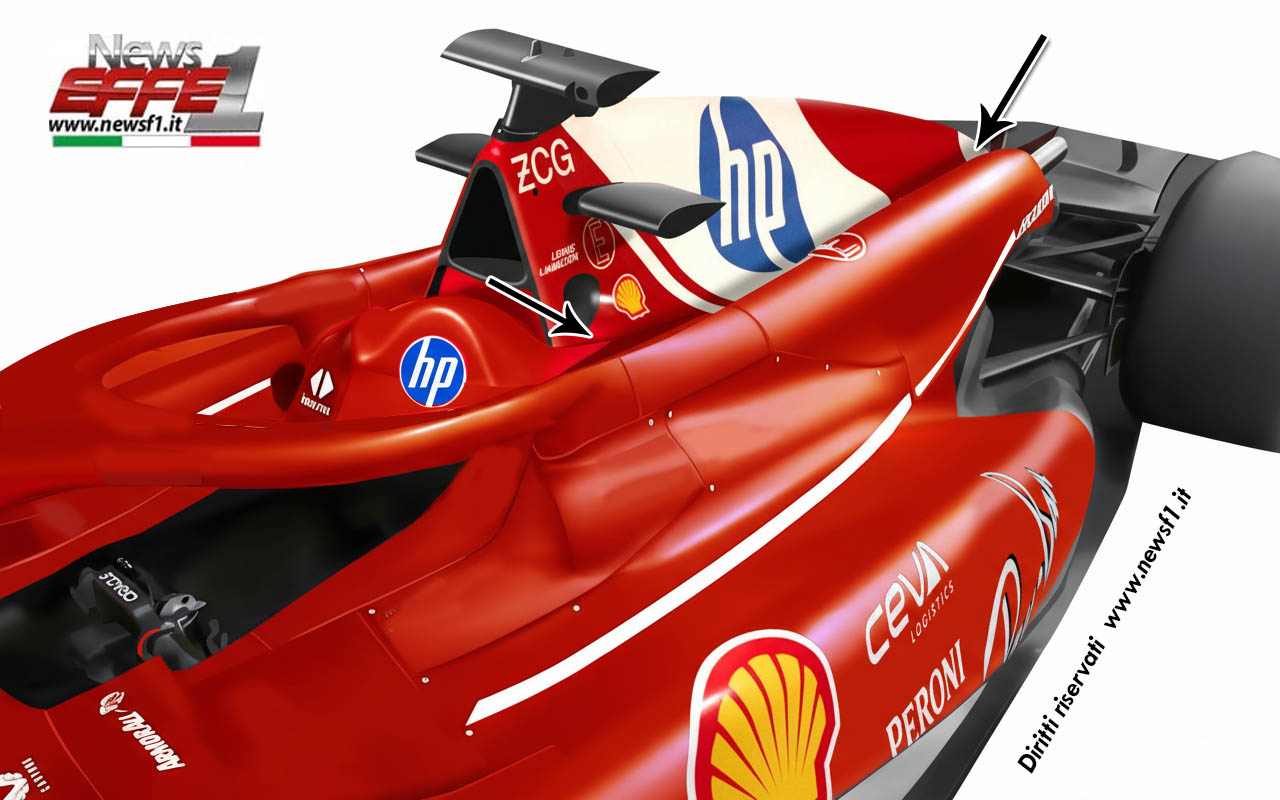

Beyond the “Innovation” Myth

Suggesting that 3D printing is a “recent discovery” for Ferrari is incorrect. The Scuderia has been using metallic 3D-printed components since 2015 (starting with the SF15-T). The real evolution lies in Design for Additive Manufacturing (DfAM)—designing parts from scratch to exploit complex geometries that were previously impossible to manufacture.

Final Analysis

Additive Manufacturing at Ferrari is a consolidated, mature technology, not a novelty. However, 3D printing cannot yet entirely replace traditional processes for critical structural components like the cylinder head. The true value of AM lies in the optimization of specific sub-components for weight reduction, thermal management, and geometric freedom.

Source:

Internal Ferrari Technical Data, Renishaw Partnership Documentation, SF15-T Technical Archives, Internal F1 Engineering sources.

Stay updated on the latest F1 technical analyses and news by visiting NewsF1.it and subscribing to our YouTube Channel.